During a recent voyage, I noticed a recording practice in the Oil Record Book (Part II) that could quietly put ships at risk of MARPOL non-compliance. Many of us follow the INTERTANKO example for documenting crude oil washing (COW). It’s clean, structured, and widely respected. But the way it’s often applied on board may place ships in an uncomfortable position.

The Problem with Grouped Entries

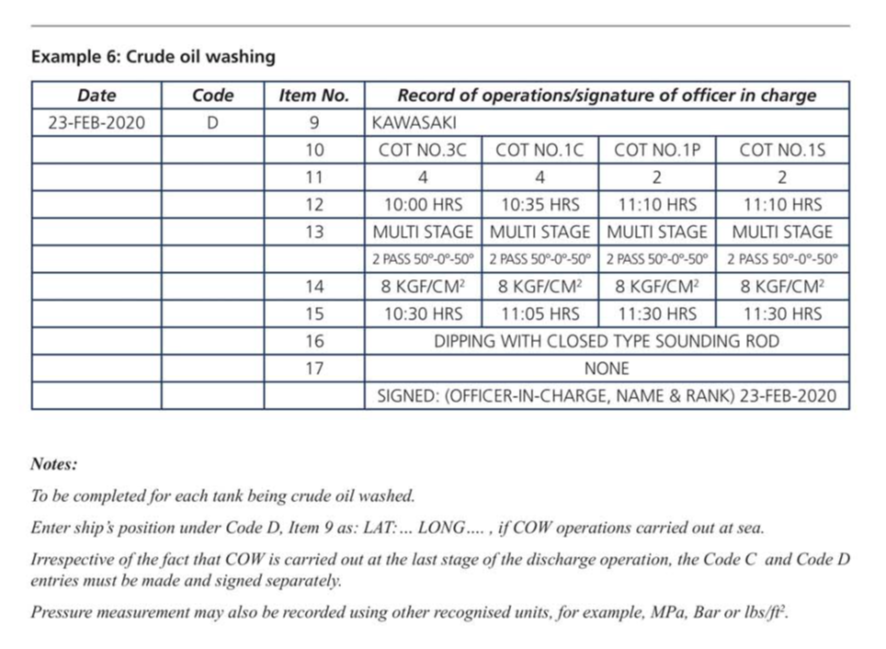

Take the INTERTANKO guide itself. In Example 6 (Crude Oil Washing), several cargo tanks are grouped together in one entry, yet each shows different start and stop times.

Strictly speaking, MARPOL Annex I Regulation 36.2 requires that “the Oil Record Book Part II shall be completed on each occasion, on a tank-to-tank basis, whenever any of the operations specified in Appendix III to the Guidelines is carried out.”

Further, MARPOL Annex I Regulation 36.2, together with Appendix III (Form of the Oil Record Book Part II), Section D Crude oil washing, specifies the particulars to be recorded for each tank: the identity of the tank(s) (item 10), number of machines in use (item 11), time washing was started and completed/stopped (items 12 and 15), the washing pattern employed (item 13), and the washing line pressure (item 14). Appendix III note 1 also requires identifying the section being washed where not all machines can be operated simultaneously (e.g., “№2C — forward section”).

Nothing in the guidance prohibits grouping, but only if tanks are washed simultaneously with identical timings. In INTERTANKO’s Example 6, the tanks clearly have different start/stop times, yet they are shown in a single block. That creates an ambiguous record, implying one continuous operation when in fact several staggered operations occurred.

Even more critically, the example does not comply with its own footnote: the location of the washing machines used is not recorded. MARPOL (Appendix III, D.13(c)) explicitly requires this information, yet the template only shows pressure and program details.

The result is a record that looks tidy on paper but fails the test of clarity and completeness. To a Port State inspector, such inconsistencies may appear at best sloppy, at worst misleading.

Why This Matters

- Port State Control: Inspectors can and do cross-check timings against actual operations. Ambiguity invites suspicion and possible detention. In fact, Port State Control data confirm this: the Tokyo MoU recorded 1,644 MARPOL Annex I deficiencies in 2024 across 32,000+ inspections, making Annex I one of the most common grounds for observations.

- U.S. courts have repeatedly convicted companies and officers for false Oil Record Books, usually ORB Part I, but the principle applies equally to Part II. Once ambiguity creeps in, it opens the same door to allegations of falsification.

- Credibility: ORB Part II is a statutory document. Vague or inconsistent entries undermine its value as legal evidence.

- Accountability: When records are challenged, it is the Master and Chief Officer who carry the burden of fines, detention, even criminal liability.

- Scope for Abuse: Ambiguous formats also create an opening for less-scrupulous operators to deliberately falsify records. Grouped or incomplete entries make it easier to conceal non-compliance while still appearing “tidy” on paper.

Simultaneous Washing: The Grey Zone

There is no explicit prohibition in MARPOL Annex I against grouping tanks when they are washed truly simultaneously under identical conditions (same start/stop times, program, pressure, and machine locations). In such cases, some operators argue that one entry is sufficient.

But Regulation 36.2 requires records to be made “on a tank-to-tank basis,” and Port State Control inspectors tend to read that literally. Even a few minutes’ variation in timings, or a difference in machine positions, can turn a grouped record into an ambiguous one.

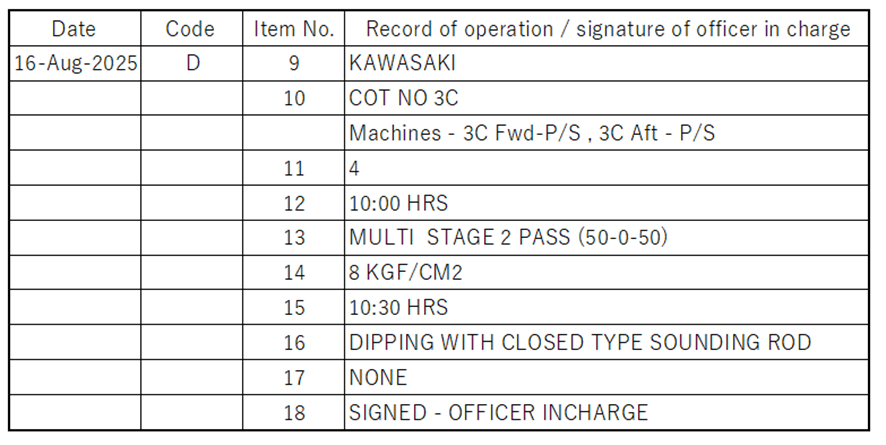

In practice, grouping may be defensible, but splitting is unchallengeable. Recording each tank separately eliminates doubt, prevents accusations of creative bookkeeping, and aligns squarely with the intent of MARPOL: clarity and traceability.

A Better Approach

To remain aligned with MARPOL’s intent and IMO’s guidelines:

- Record one tank per line unless operations are truly simultaneous.

- Always identify the washing machine positions used for each tank.

- Avoid grouping after the fact, as it creates ambiguity and potential exposure.

The Inspector’s Angle

In practice, inspectors under SIRE 2.0 rarely challenge entries that follow INTERTANKO’s template after all, the guide itself is referenced in the inspection tablet. On the surface, this reduces friction: if the book looks like the example, it passes.

But the danger is more insidious. A flawed template, once adopted into inspection culture, becomes the norm. Operators who log tank-by-tank, fully compliant with MARPOL, may find themselves questioned simply because their entries “look different.” Meanwhile, less scrupulous operators can hide behind the ambiguity of grouped records, confident that inspectors are conditioned to accept the format at face value.

The net effect? Conformity with a guidebook example starts to matter more than actual compliance with MARPOL. That inversion of priorities is precisely where risk, inconsistency, and liability creep in.

Respectfully, a Call for Review

Intertanko’s guidance has long brought consistency to ORB entries. But Example 6 shows how practice can drift away from MARPOL’s actual requirements. It may be time for INTERTANKO and other industry bodies to revisit their crude oil washing examples to ensure they align fully with the regulation.

INTERTANKO’s examples were meant as guidance, not gospel. But if industry bodies do not update them, we risk teaching officers to keep records that fail MARPOL. That is a compliance trap we can and must fix.

Leave a comment